Hyundai Palisade: Engine Control System / CVVT Oil Control Valve (OCV)

Hyundai Palisade (LX2) 2020-2025 Service Manual / Engine Control/Fuel System / Engine Control System / CVVT Oil Control Valve (OCV)

Description and operation

| Description |

Continuous Variable Valve Timing (CVVT) system advances or retards the valve

timing of the intake and exhaust valve in accordance with the ECM control signal

which is calculated by the engine speed and load.

By controlling CVVT, the valve overlap or underlap occurs, which in turn improves

fuel efficiency, reduces exhaust gases (NOx, HC) and improves engine performance

by reducing pumping loss, generating internal EGR effect, improving combustion

stability, improving volumetric efficiency and increasing expansion work.

This system consists of the CVVT Oil Control Valve (OCV) which supplies the

engine oil to the cam phaser or spills the engine oil from the cam phaser in

accordance with the ECM PWM (Pulse With Modulation) control signal, the CVVT

Oil Temperature Sensor (OTS) which measures the engine oil temperature, and

the Cam Phaser which varies the cam phase by using the hydraulic force of the

engine oil.

The engine oil which is supplied through the CVVT oil control valve varies the

cam phase in the direction (Intake Advance/Exhaust Retard) or opposite direction

(Intake Retard/Exhaust Advance) of the engine rotation by rotating the rotor

connected with the camshaft inside the cam phaser.

CVVT Oil Control Valve (OCV) [Banks 1, 2 / Exhaust]

Specifications

| Specification |

|

Item |

Specification |

|

Coil Resistance (Ω) |

6.9 - 7.9 [20°C (68°F)] |

Troubleshooting

| Signal Waveform |

Schematic diagrams

| Circuit Diagram |

Harness Connector

Repair procedures

| Inspection |

| 1. |

Switch "OFF" the ignition.

|

| 2. |

Disconnect the OCV connector.

|

| 3. |

Measure resistance between the OCV terminals 1 and 2.

|

| 4. |

Check that the resistance is within the specification.

|

| Removal |

CVVT Oil Control Valve [Bank 1 / Exhaust]

| 1. |

Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

|

| 2. |

Remove the cylinder head cover.

(Refer to Engine Mechanical System - "Cylinder Head Assembly")

|

| 3. |

Remove the installation bolt (A), and then remove the valve from the

engine.

|

CVVT Oil Control Valve [Bank 2 / Exhaust]

| 1. |

Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

|

| 2. |

Remove the cylinder head cover.

(Refer to Engine Mechanical System - "Cylinder Head Assembly")

|

| 3. |

Remove the installation bolt (A), and then remove the valve from the

engine.

|

| Installation |

|

|

Items |

Component Side |

Harness Side |

|

Bank 1 (RH) |

Grey |

|

|

Bank 2 (LH) |

Black |

|

| 1. |

Install in the reverse order of removal.

|

Variable Force Solenoid (VFS)

Variable Force Solenoid (VFS)

Description and operation

Description

Continuous Variable Valve Timing (CVVT) system advances or retards the valve

timing of the intake and exhaust valve in accordance with the ECM control signal

which is calculated by the engine speed and load...

Variable Intake Solenoid (VIS) Valve

Variable Intake Solenoid (VIS) Valve

Description and operation

Description

Installed on the intake manifold (VIS Valve 1) and the surge tank (VIS Valve

2), the Variable Intake manifold Solenoid (VIS) valves 1 and 2 control the vacuum

modulators, which activate the valves in the intake manifold and the surge tank...

Other information:

Hyundai Palisade (LX2) 2020-2025 Service Manual: 28 Brake Control Solenoid Valve (28/B_VFS)

Description and operation Description • When TCM supplies variable current to solenoid valve, hydraulic pressure of 28 brake is controlled directly by solenoid valve. • 28 Brake control solenoid valve is a Variable Force Solenoid (VFS) type...

Hyundai Palisade (LX2) 2020-2025 Service Manual: Description and operation

Description MDPS (Motor Dirven Power Steering) system uses an electric motor to assist the steering force and it is an engine operation independent steering system. MDPS control module controls the motor operation according to information received from the each sensor and CAN (Controller Area Network), resulting in a more precise and timely control of steering assist than conventional engine-driven hydraulic systems...

Categories

- Manuals Home

- 1st Generation Palisade Owners Manual

- 1st Generation Palisade Service Manual

- Changing Tires

- Check Tire Pressure

- Emergency liftgate safety release

- New on site

- Most important about car

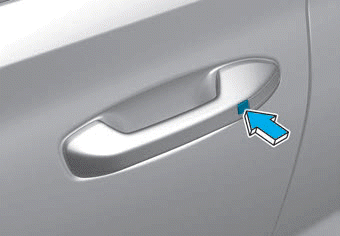

Locking your vehicle

To lock your vehicle using the door handle button or the Smart Key:

1.Make sure all doors, the hood and the liftgate are closed.

2.Make sure you have the smart key in your possession.

Copyright © 2025 www.hpalisadelx.com