Hyundai Palisade (LX2): Timing System / Timing Chain

Repair procedures

| Removal |

|

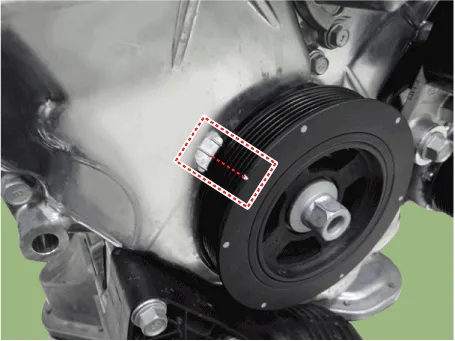

| 1. |

Set No.1 cylinder to TDC/compression.

|

| 2. |

Remove the timing chain cover.

(Refer to Timing System - "Timing Chain Cover")

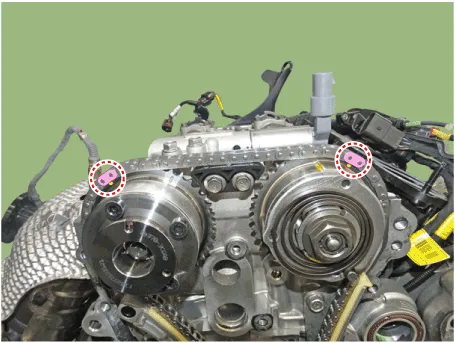

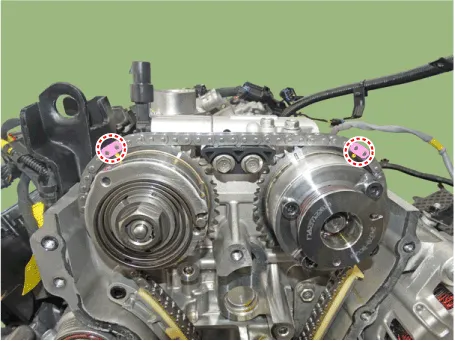

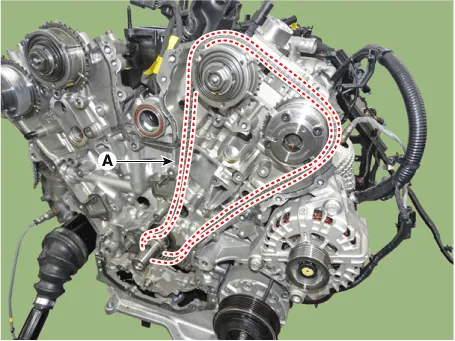

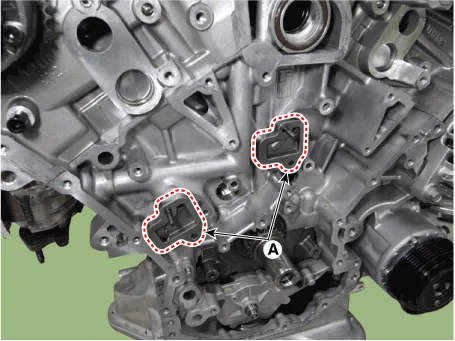

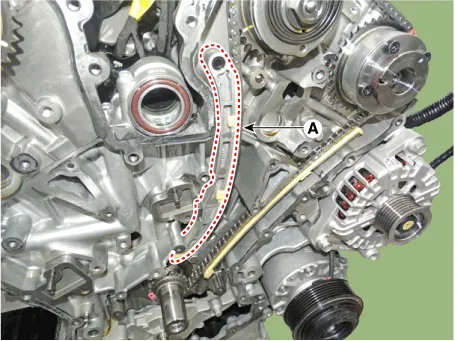

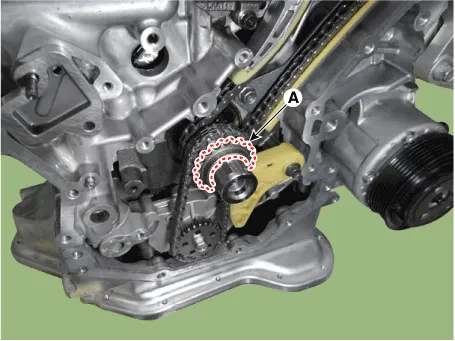

[RH]

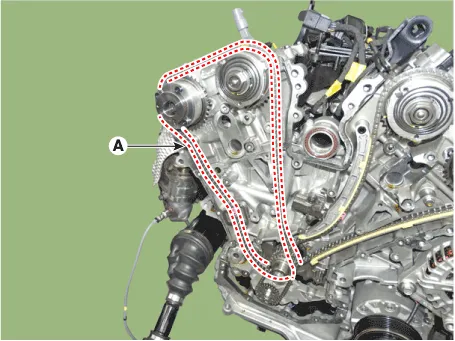

[LH]

|

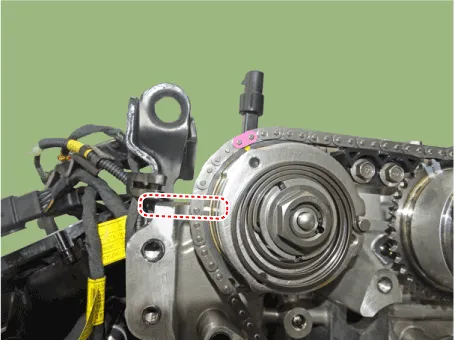

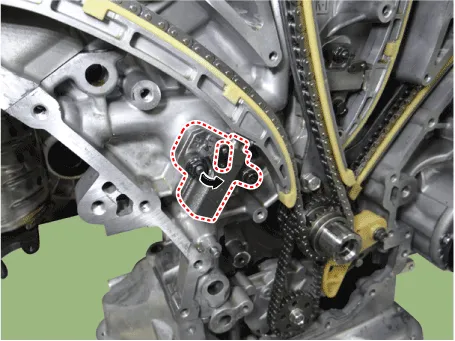

| 3. |

Release the ratchet by pulling the link down using a thin rod. Compress

the piston and then insert a stopper pin into the hole on the ratchet

to hold the compressed piston.

|

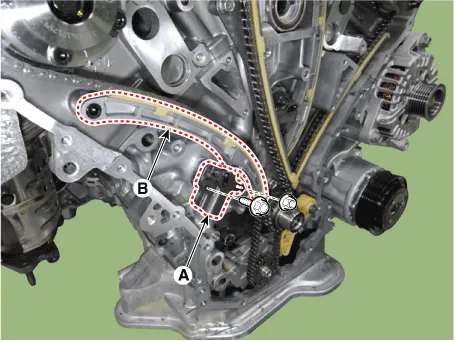

| 4. |

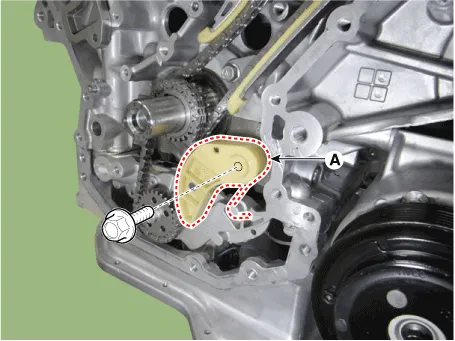

Remove the RH timing chain cam to cam guide (A).

|

| 5. |

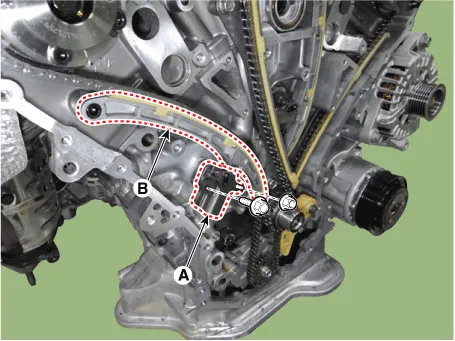

Remove the RH timing chain auto tensioner (A) and the RH timing chain

tensioner arm (B).

|

| 6. |

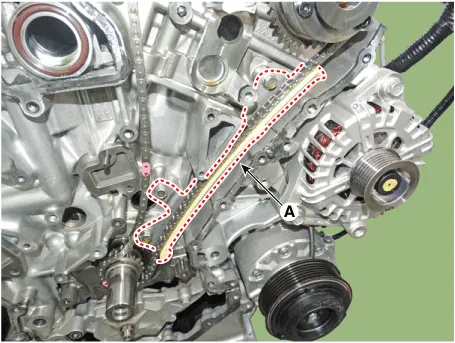

Remove the RH timing chain guide (A).

|

| 7. |

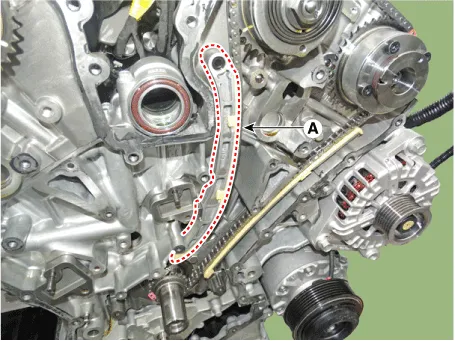

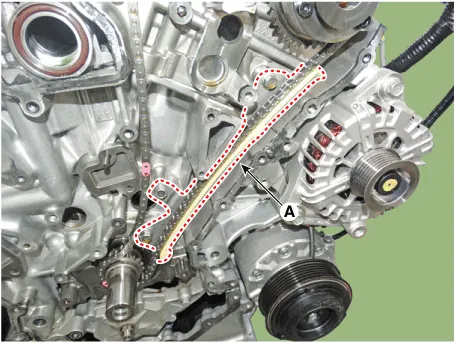

Remove the RH timing chain (A).

|

| 8. |

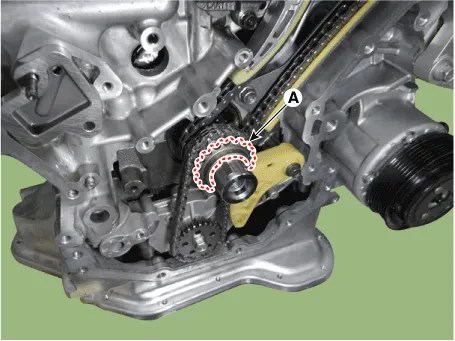

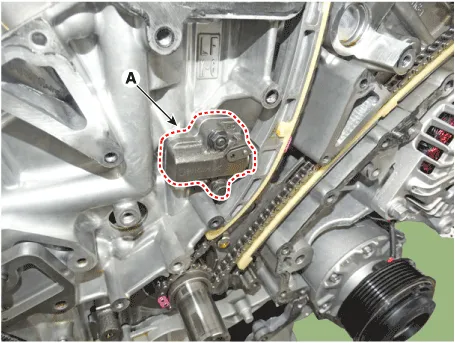

Remove the oil pump chain tensioner assembly (A).

|

| 9. |

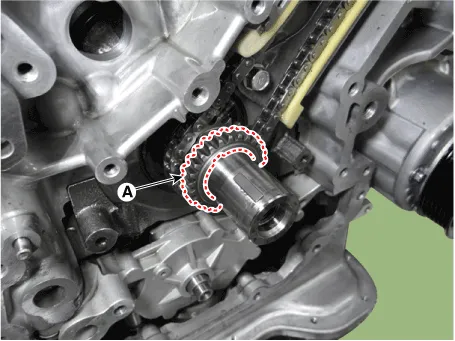

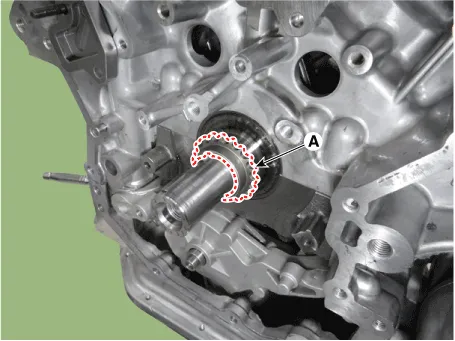

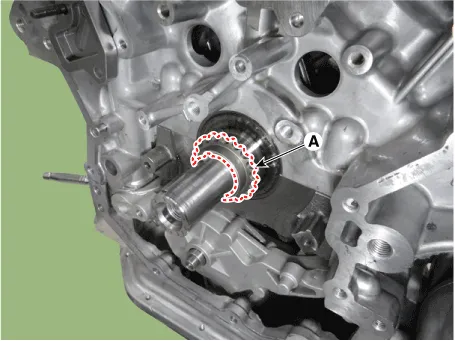

Remove the crankshaft chain sprocket (A) (RH camshaft drive).

|

| 10. |

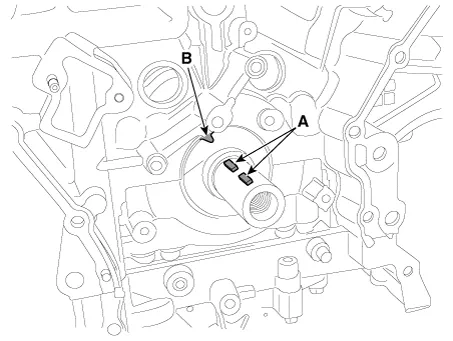

Remove the oil pump chain sprocket (A) and oil pump chain (B).

|

| 11. |

Remove the crankshaft sprocket (A) (Oil pump drive).

|

| 12. |

Release the ratchet by pulling the link down using a thin rod. Compress

the piston and then insert a stopper pin into the hole on the ratchet

to hold the compressed piston.

|

| 13. |

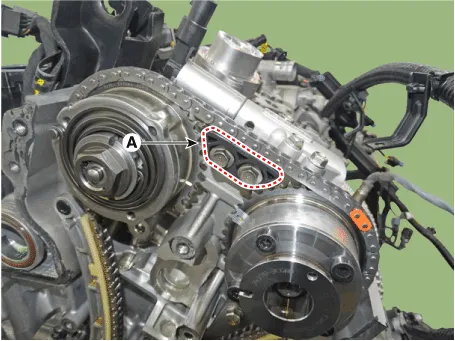

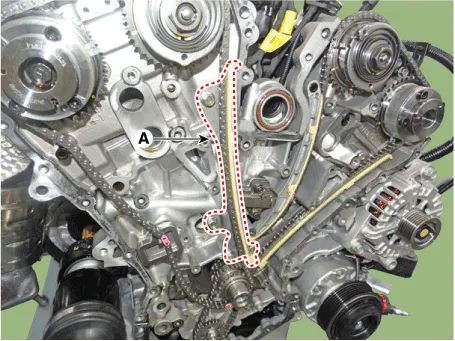

Remove the LH timing chain cam to cam guide (A).

|

| 14. |

Remove the LH timing chain auto tensioner (A).

|

| 15. |

Remove the LH timing chain tensioner arm (A).

|

| 16. |

Remove the LH timing chain guide (A).

|

| 17. |

Remove the LH timing chain (A).

|

| 18. |

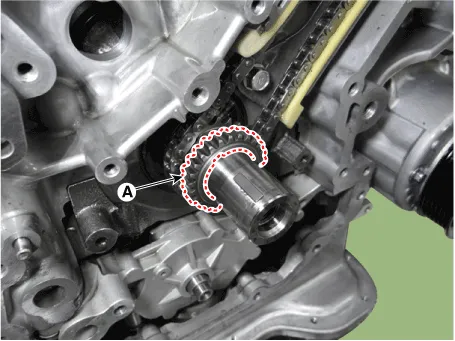

Remove the crankshaft chain sprocket (A). (LH camshaft drive).

|

| 19. |

Remove the tensioner adapter assembly (A).

|

| Inspection |

| 1. |

Check the camshaft sprocket and crankshaft sprocket for abnormal wear,

cracks, or damage. Replace as necessary.

|

| 2. |

Inspect the tensioner arm and chain guide for abnormal wear, cracks,

or damage. Replace as necessary.

|

| 3. |

Check that the tensioner piston moves smoothly when the ratchet pawl

is released with thin rod.

|

| Installation |

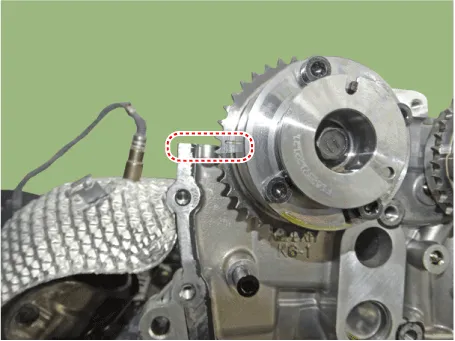

| 1. |

The key (A) of crankshaft should be aligned with the timing mark (B)

of block. As a result of this, the piston of No.1 cylinder is placed

at the top dead center on compression stroke.

|

| 2. |

Install the tensioner adapter assembly (A).

|

| 3. |

Install the crankshaft chain sprocket (A). (LH camshaft drive).

|

| 4. |

Install the LH timing chain (A).

|

| 5. |

Install the LH timing chain guide (A).

|

| 6. |

Install the LH timing chain tensioner arm (A).

|

| 7. |

Install the LH timing chain auto tensioner (A).

|

| 8. |

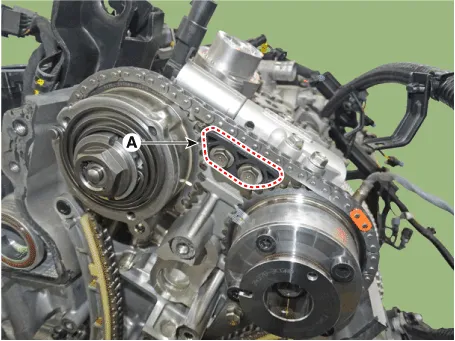

Install the LH timing chain cam to cam guide (A).

|

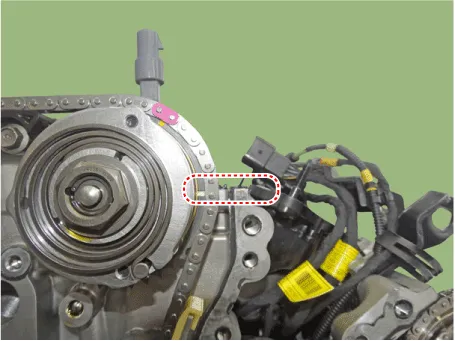

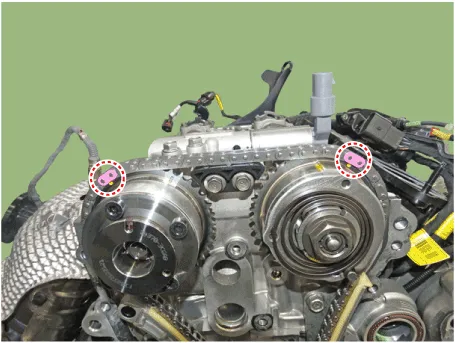

| 9. |

Pull out the pins (A) of LH timing chain auto tensioner.

|

| 10. |

Install the crankshaft sprocket (A) (Oil pump drive).

|

| 11. |

Install the oil pump chain sprocket (A) and oil pump chain (B).

|

| 12. |

Install the oil pump chain tensioner assembly (A).

|

| 13. |

Install the camshaft chain sprocket (A). (RH camshaft drive)

|

| 14. |

Install the RH timing chain (A).

|

| 15. |

Install the RH timing chain guide (A).

|

| 16. |

Install the RH timing chain auto tensioner (A) and the RH timing chain

tensioner arm (B).

|

| 17. |

Install the RH timing chain cam to cam guide (A).

|

| 18. |

Pull out the pins (A) of RH timing chain auto tensioner.

|

| 19. |

After rotating the crankshaft 2 revolutions in regular direction (clockwise

viewed from front), confirm the timing mark.

|

| 20. |

Install the timing chain cover.

(Refer to Timing System - "Timing Chain Cover")

|

| 21. |

Install the remaining parts in the reverse order of removal.

|

Repair procedures Removal • Be careful not to damage the parts located under the vehicle (floor under cover, fuel filter, fuel tank and canister) when raising the vehicle using the lift.

Other information:

Hyundai Palisade (LX2) 2020-2026 Service Manual: Repair procedures

Refrigerant System Service Basics (R-134a) Refrigerant Recovery Use only service equipment that is U.L-listed and is certified to meet the requirements of SAE J2210 to remove HFC-134a(R-134a) from the air conditioning system.

Hyundai Palisade (LX2) 2020-2026 Service Manual: Smart Cruise Control (SCC) Switch

Components and components location Components 1. Remote control switch (Audio swtich) 2. Remote control switch (Cruise control switch) Schematic diagrams Circuit Diagram Trip + SCC Repair procedures Removal 1.

Categories

- Manuals Home

- Hyundai Palisade Owners Manual

- Hyundai Palisade Service Manual

- Removing and Storing the Spare Tire

- Electrochromatic Mirror (ECM) with homelink system

- Emergency liftgate safety release

- New on site

- Most important about car