Hyundai Palisade (LX2): Air conditioning System / Refrigerant Line

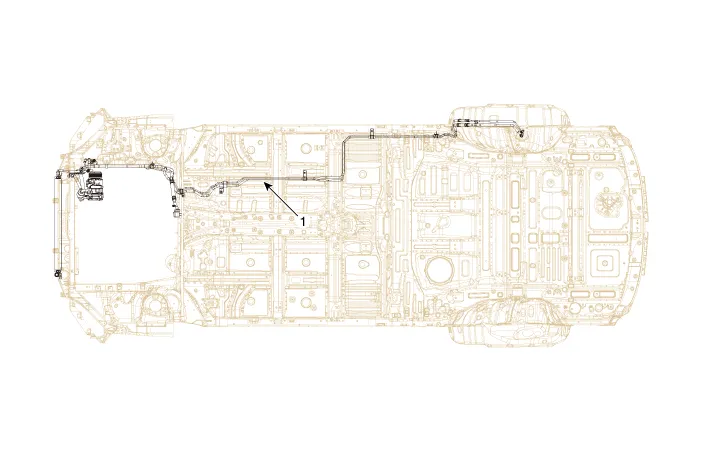

Components and components location

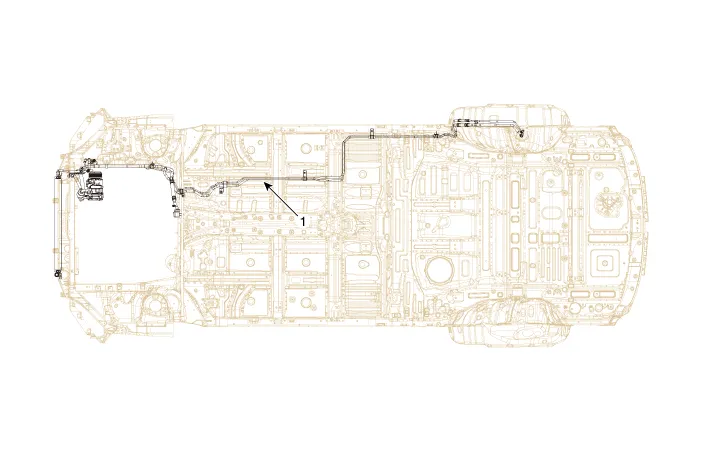

[Isometric view]

1. Front suction & Liquid pipe

assembly

|

|

[Top view]

1. Front suction & Liquid pipe

assembly

|

|

Repair procedures

[Front suction & Liquid pipe assembly]

| 1. |

If a compressor is available, the air conditioner is operated for a

few minutes in the engine idle state and then the engine is stopped.

|

| 2. |

Disconnect the negative (-) battery terminal.

|

| 3. |

Recover the refrigerant with a recovery/charging station.

|

| 4. |

Remove the engine cover.

(Refer to Engine Mechanical System - "Engine Cover")

|

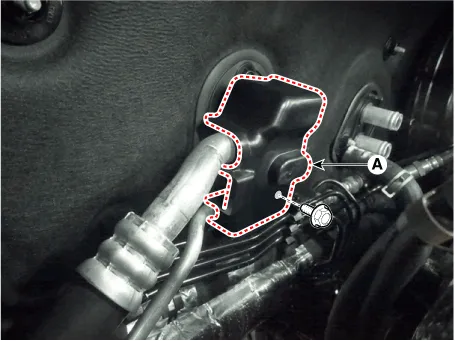

| 5. |

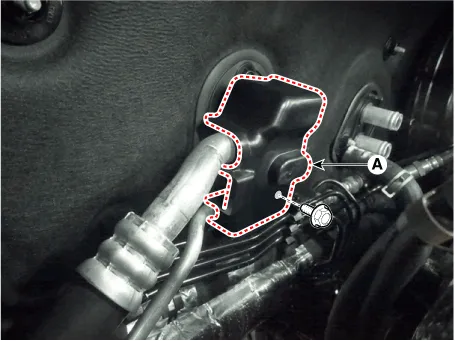

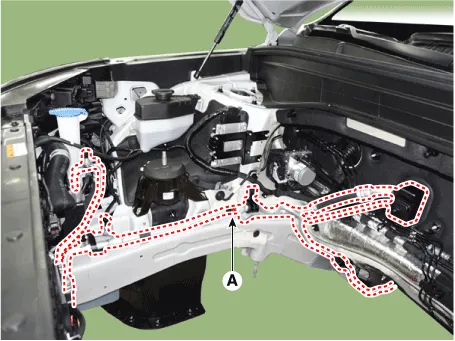

Loosen the mounting nut and remove the expansion valve cover (A).

|

Tightening torque :

8.8 - 13.7 N.m (0.9 - 1.4 kgf.m, 6.5 - 10.1 lb-ft)

|

|

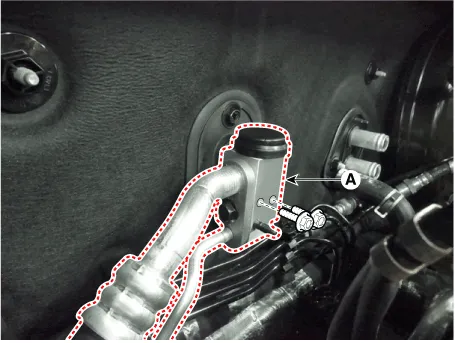

| 6. |

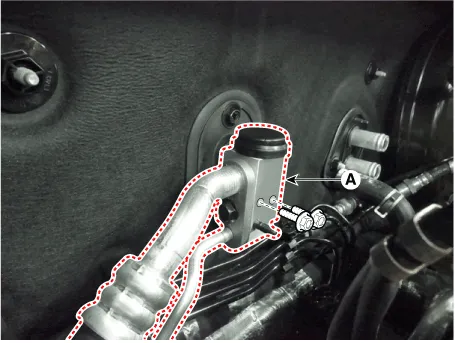

Loosen the mounting bolts and separate the expansion valve (A) fron

evaporator core.

|

Tightening torque :

8.8 - 13.7 N.m (0.9 - 1.4 kgf.m, 6.5 - 10.1 lb-ft)

|

|

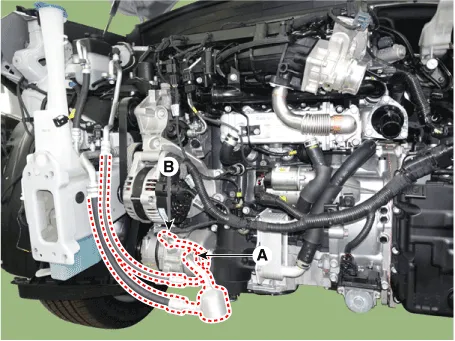

| 7. |

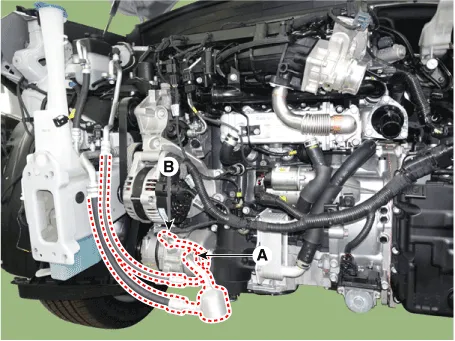

Loosen the mounting nuts and separate the suction line (A), discharge

line (B).

|

Tightening torque :

19.6 - 23.5 N.m (2.0 - 2.4 kgf.m, 14.5 - 17.4 lb-ft)

|

|

| 8. |

Press the lock pin and separate the APT (Air conditioning Pressure Transducer)

sensor connector (A).

|

| 9. |

Remove the engine room under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

|

| 10. |

Remove the engine mounting braket.

(Refer to Engine Mechanical System - "Engine Mounting")

|

| 11. |

Separate the compressor suction line (A) and discharge line (B) connection

nuts and disconnect the line.

|

Tightening torque :

20.9 - 31.2 N.m (2.1 - 3.2 kgf.m, 15.4 - 23.0 lb-ft)

|

| •

|

Be careful not to damage the parts located under the

vehicle (floor under cover, fuel filter, fuel tank and

canister) when raising the vehicle using the lift.

(Refer to General Information - "Lift and Support Points")

|

|

|

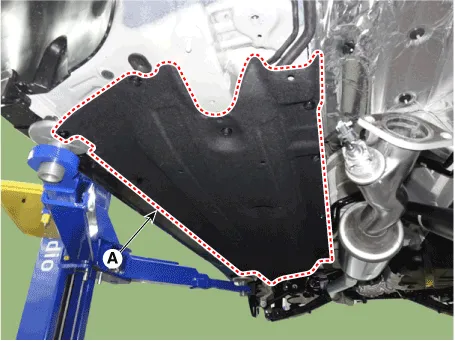

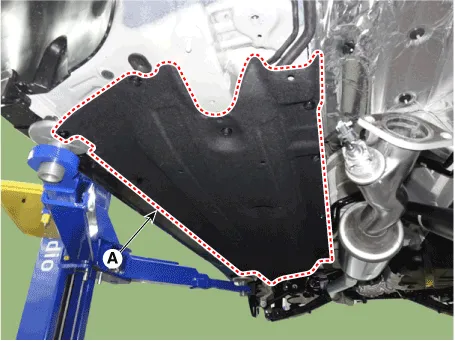

| 12. |

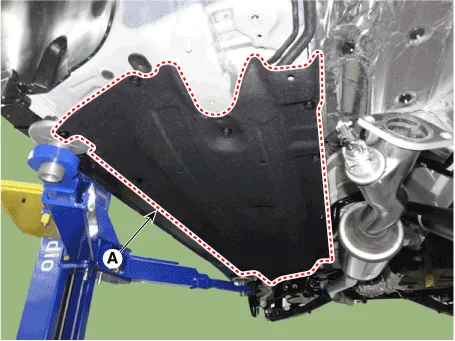

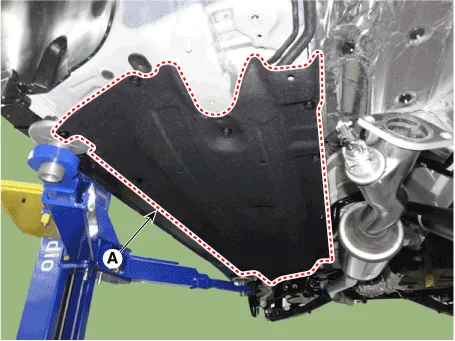

Loosen the mounting bolts, nuts and remove the engine room under cover

[RH] (A).

|

Tightening torque

8.8 - 13.7 N.m (0.9 - 1.4 kgf.m, 6.5 - 10.1 lb-ft)

|

|

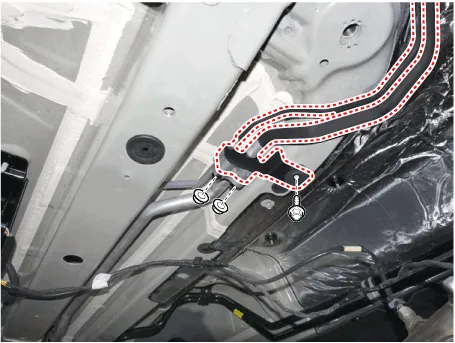

| 13. |

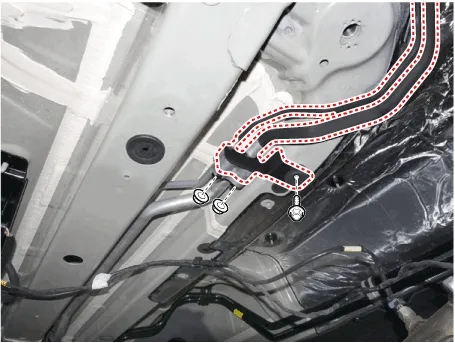

Remove the refrigerant pipe line mounting nuts and braket bolt.

|

Tightening torque :

Nut : 8.8 - 13.7 N.m (0.9 - 1.4 kgf.m, 6.5 - 10.1 lb-ft)

Bolt : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

|

|

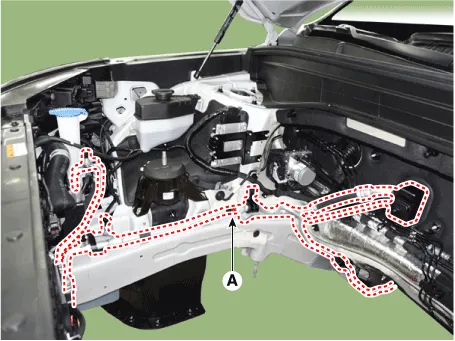

| 14. |

Loosen the mounting bolt and remove the Front suction & Liquid pipe

assembly (A).

|

Tightening torque :

7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

|

|

| 15. |

To install, reverse removal procedure.

|

| • |

Plug or cap the lines immediately after disconnecting them to

avoid moisture and dust contamination.

|

| • |

Tighten the bolt or nut joint to the specified torque.

|

| • |

Using a gas leak detector, check for refrigerant leakage.

|

| • |

Evacuate air in the refrigeration system and charge system with

refrigerant.

|

|

[Rear Suction & Liquid Pipe Assembly]

| 1. |

If a compressor is available, the air conditioner is operated for a

few minutes in the engine idle state and then the engine is stopped.

|

| 2. |

Disconnect the negative (-) battery terminal.

|

| 3. |

Recover the refrigerant with a recovery/charging station.

|

| 4. |

Remove the rear wheel guard [RH].

(Refer to Body - "Rear Wheel Guard")

|

| 5. |

Loosen the mounting nuts and separate the suction line, discharge line

(A).

|

Tightening torque :

19.6 - 23.5 N.m (2.0 - 2.4 kgf.m, 14.5 - 17.4 lb-ft)

|

|

| 6. |

Loosen the mounting bolts, nuts and remove the engine room under cover

[RH] (A).

|

Tightening torque :

8.8 - 13.7 N.m (0.9 - 1.4 kgf.m, 6.5 - 10.1 lb-ft)

|

|

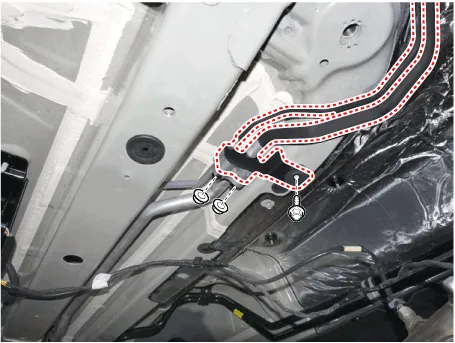

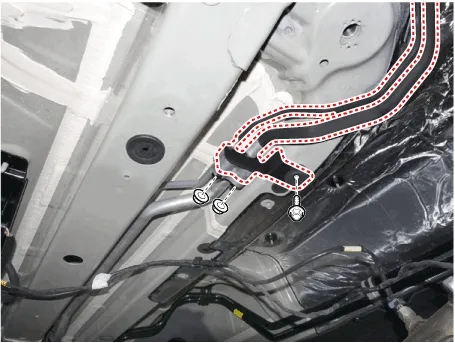

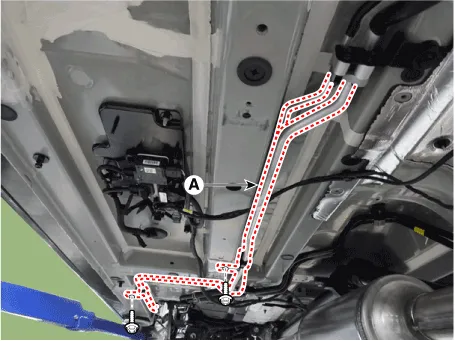

| 7. |

Remove the refrigerant pipe line mounting nuts.

|

Tightening torque :

8.8 - 13.7 N.m (0.9 - 1.4 kgf.m, 6.5 - 10.1 lb-ft)

|

|

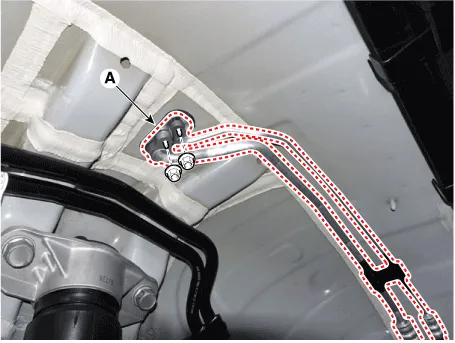

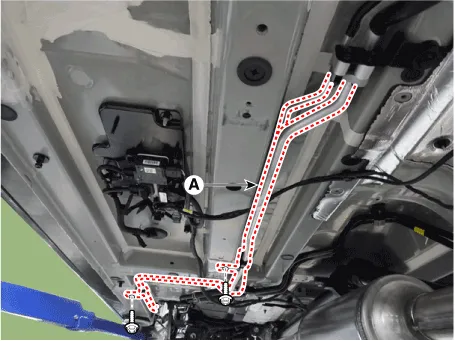

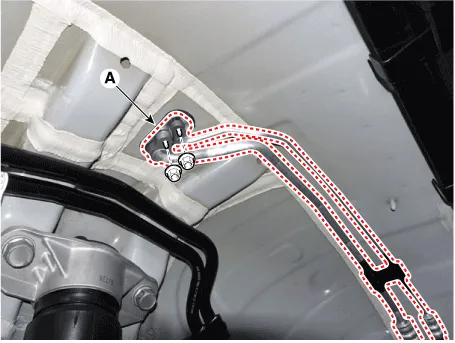

| 8. |

Loosen the mounting bolt and remove the Rear suction & Liquid pipe assembly

(A).

|

Tightening torque :

7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

|

|

| 9. |

To install, reverse removal procedure.

|

| • |

Plug or cap the lines immediately after disconnecting them to

avoid moisture and dust contamination.

|

| • |

Tighten the bolt or nut joint to the specified torque.

|

| • |

Using a gas leak detector, check for refrigerant leakage.

|

| • |

Evacuate air in the refrigeration system and charge system with

refrigerant.

|

|

Repair procedures

Oil Specification

1.

The R-134a or R-1234yf system requires synthetic (PAG) compressor oil

whereas the R-12 system requires mineral compressor oil.

Description and operation

Description

The compressor is the power unit of the A/C system.

It is located on the side of engine block and driven by a V-belt of the engine.

Other information:

Inspection

Tolerance Compensation

Tolerance compensation compensates for the error margins of around view video

that occur due to the installation tolerance when the four cameras that comprise

the SVM system are installed.

You must carry out tolerance compensation if you do any of the following.

System Block Diagram

Component Parts And Function Outline

Component part

Function

Vehicle-speed sensor, ESP/ABS Control Module

Converts vehicle speed to pulse.

ECM

Receives signals from sensor and control switches.