Hyundai Palisade (LX2): Engine Control System / Rail Pressure Sensor (RPS)

Description and operation

| Description |

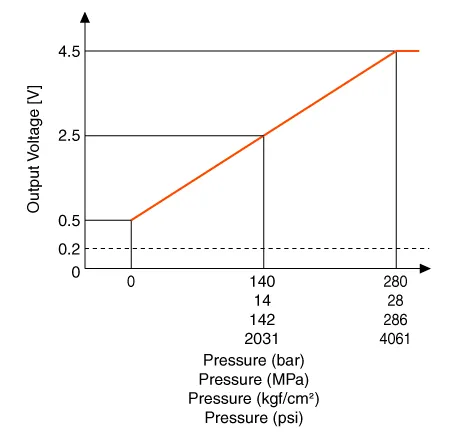

Specifications

| Specification |

|

Pressure |

Output Voltage (V) [Vref=5V] |

|

|

bar |

[MPa (kgf/cm², psi)] |

|

|

0 |

0 (0, 0) |

0.5 |

|

140 |

14 (142, 2031) |

2.5 |

|

280 |

28 (286, 4061) |

4.5 |

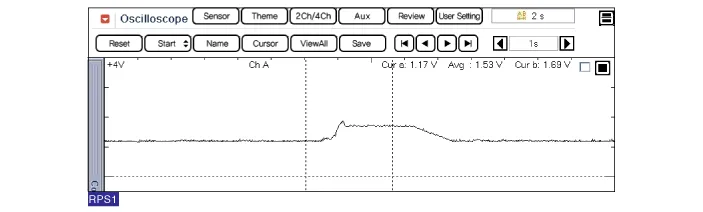

Troubleshooting

| Signal Waveform |

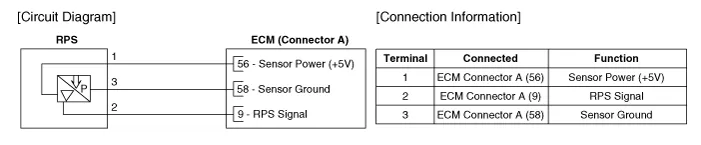

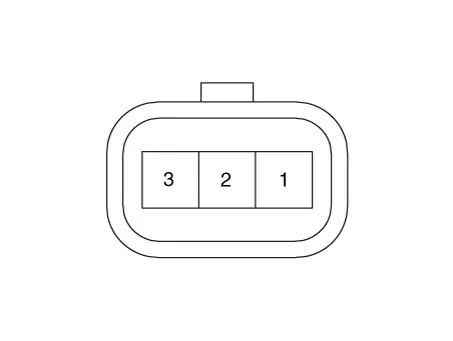

Schematic diagrams

| Circuit Diagram |

Repair procedures

| Inspection |

| 1. |

Connect the diagnostic tool on the Data Link Connector (DLC).

|

| 2. |

Measure the output voltage of the RPS at idle and various engine speed.

|

||||||||||||||

| Removal |

| 1. |

Release the residual pressure in fuel line.

(Refer to Fuel Delivery System - "Release Residual Pressure in Fuel

Line")

|

| 2. |

Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

|

| 3. |

Remove the intake manifold.

(Refer to Engine Mechanical System - "Intake Manifold")

|

| 4. |

Disconnect the rail pressure sensor connector (A), and then remove the

sensor (B) from the delivery pipe.

|

| Installation |

|

| 1. |

Install in the reverse order of removal.

|

Description and operation Description Heated Oxygen Sensor (HO2S), consisting of zirconium and alumina, is installed on both upstream and downstream of the Manifold Catalytic Converter (MCC) to detect the air/fuel ratio and send it to the ECM.

Description and operation Description Continuous Variable Valve Timing (CVVT) system advances or retards the valve timing of the intake and exhaust valve in accordance with the ECM control signal which is calculated by the engine speed and load.

Other information:

Hyundai Palisade (LX2) 2020-2026 Service Manual: Ambient Temperature Sensor

Description and operation Description The ambient temperature sensor is located at the front of the condenser and detects ambient air temperature. It is a negative type thermistor; resistance will increase with lower temperature, and decrease with higher temperature.

Hyundai Palisade (LX2) 2020-2026 Service Manual: Repair procedures

Inspection 1. Turn the ignition switch ON. 2. Manually operate the control switch and measure the voltage of the blower motor. 3. Select the control switch to raise the voltage until it reaches high speed.

Categories

- Manuals Home

- Hyundai Palisade Owners Manual

- Hyundai Palisade Service Manual

- Rear Bumper Cover

- General Tightening Torque Table

- Body Electrical System

- New on site

- Most important about car