Hyundai Palisade (LX2): Fuel Delivery System / High Pressure Fuel Pump

Hyundai Palisade (LX2) 2020-2026 Service Manual / Engine Control/Fuel System / Fuel Delivery System / High Pressure Fuel Pump

Repair procedures

| Removal |

| 1. |

Release the residual pressure in fuel line.

(Refer to Fuel Delivery System - "Release Residual Pressure in Fuel

Line")

|

| 2. |

Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

|

| 3. |

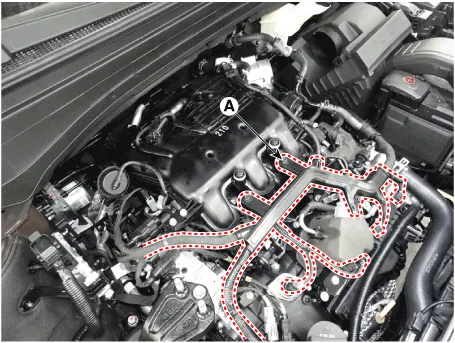

Remove the high pressure fuel pump foam (A).

|

| 4. |

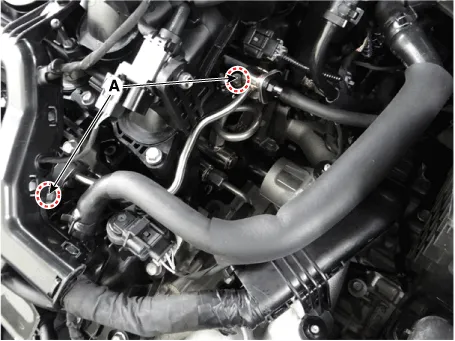

Remove the control wiring harness (A).

|

| 5. |

Remove the fuel line mounting bolts (A).

|

| 6. |

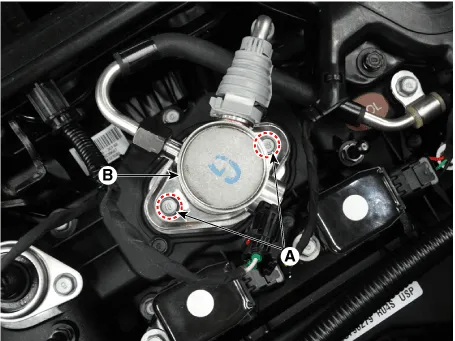

Disconnect the high pressure fuel control valve connector (A) and low

pressure fuel feed tube quick-connector (B).

|

| 7. |

Remove the high pressure fuel pipe.

(Refer to Fuel Delivery System - "Fuel Line")

|

| 8. |

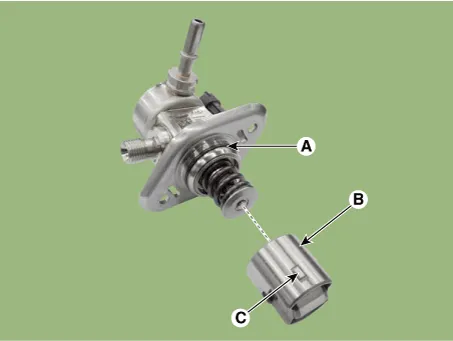

Remove the mounting bolts (A), and then remove the high pressure fuel

pump (B) from the cylinder head assembly.

|

| Installation |

|

|

|

|

| 1. |

Install in the reverse order of removal.

|

Repair procedures Removal • When removing the high pressure fuel pump, high pressure fuel pipe, delivery pipe, and injector, injury may be caused by leakage of high pressure fuel.

Other information:

Hyundai Palisade (LX2) 2020-2026 Service Manual: Components and components location

Component Location 1. Start Stop Button(SSB) 2. FOB key 3. Tailgate open switch 4. Interior antenna 1 5. Interior antenna 2 6. Intergrated Body Control Unit (IBU) 7. Trunk antenna 8. Door handle & door antenna 9.

Hyundai Palisade (LX2) 2020-2026 Service Manual: Components and components location

Categories

- Manuals Home

- Hyundai Palisade Owners Manual

- Hyundai Palisade Service Manual

- Convenient Features of Your Vehicle

- Automatic Transaxle Fluid (ATF)

- Lift and Support Points

- New on site

- Most important about car

Copyright © 2026 www.hpalisadelx.com - 0.0144