Hyundai Palisade (LX2): Automatic Transaxle Control System / Position Sensor

Specifications

| Specification |

|

Item |

Specification |

|

|

Power supply (V) |

4.5 - 5.5V |

|

|

Output type |

Shifting range |

Non-contact (2 channel PWM signal) |

Description and operation

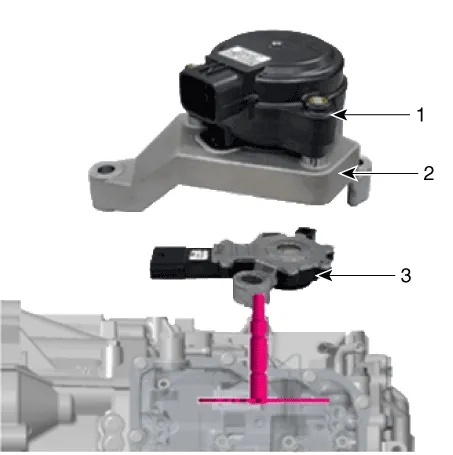

| Description |

| 1. Electric shift actuator

2. Bracket 3. Position sensors |

Troubleshooting

| Troubleshooting |

|

Major Symptom |

Expected Cause |

Items to Check and Measures |

|

Shock when shifting to and from D/R Motor run-up when shifting to and from D/R |

Faulty position sensor "N" setting |

Use the "N" setting jig and adjust the "N" setting. (Refer to "Automatic Transaxle System – Position Sensor") |

|

Faulty oil pressure in the valve body |

Replace valve body assembly or inspect/replace transaxle assembly |

|

|

Faulty engine start Current gear not indicated in the Cluster Warning Lamp ON Engine stall while stopped Creeping not possible Auto parking release disabled |

Faulty CAN terminating resistance/circuit |

Check TCM/battery management system module. |

|

Check TCM wiring connector connection. |

||

|

Faulty position sensor circuit fuse |

Check fuse and junction box terminal, and repair. |

|

|

Faulty position sensor wiring connector |

Check for foreign substance in the wiring connector, and check for gap on

the terminal. |

|

|

Check sealing on unused pin, and check for corrosion on the terminal. |

||

|

Faulty reverse lamp circuit |

Check reverse lamp ground, and reassemble if necessary. |

|

|

Faulty position sensor wiring ground |

Check wiring ground, and reassemble if necessary. |

|

|

Position sensor faulty code |

Inspect in accordance with the inspection flow, then replace position sensor

if necessary. |

Repair procedures

| Removal |

|

| 1. |

Turn ignition switch OFF and disconnect the negative (-) battery cable.

|

| 2. |

Remove the battery and battery tray.

(Refer to Engine Electrical System - "Battery")

|

| 3. |

Remove the air duct and the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

|

| 4. |

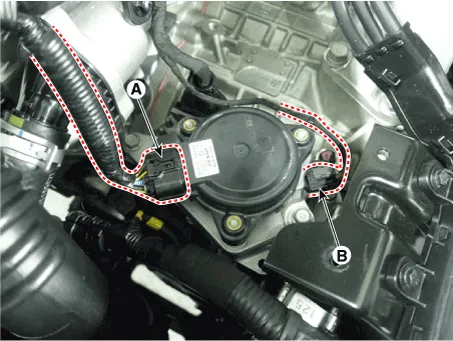

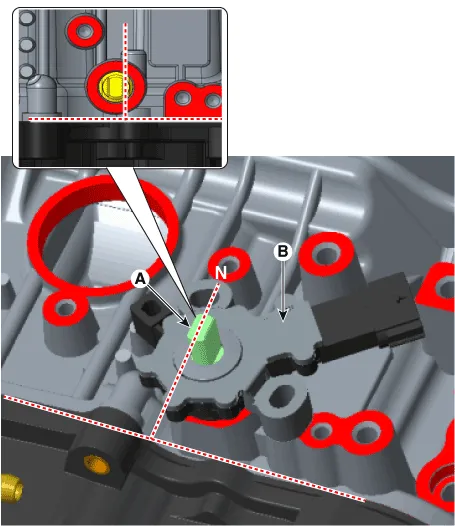

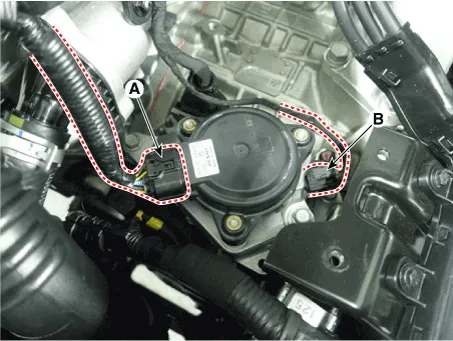

Disconnect the position sensor connector (A).

|

| 5. |

Disconnect the electronic shift actuator connector (B).

|

| 6. |

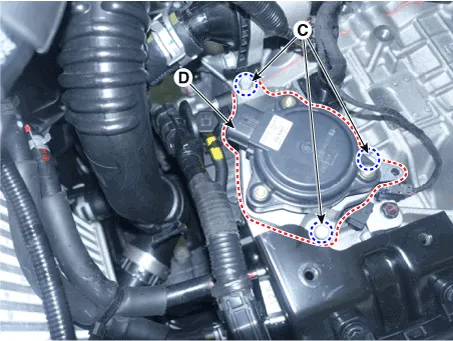

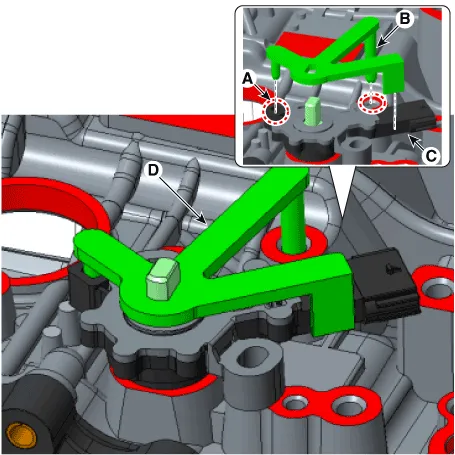

Remove the electronic shift actuator (D) after removing the bolts (C).

|

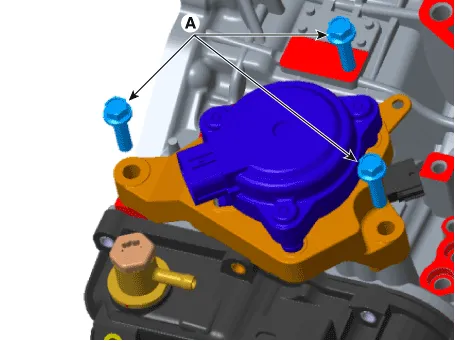

| 7. |

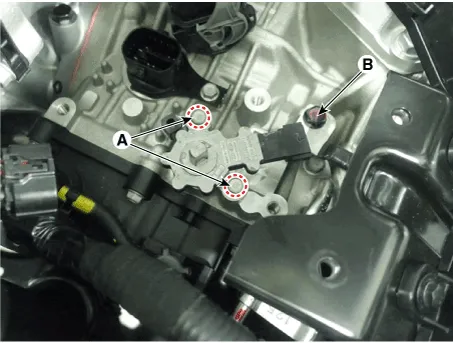

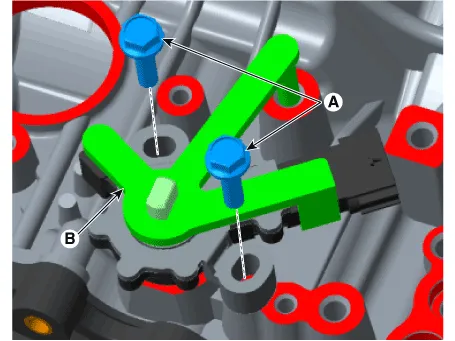

Remove the position sensor (B) after removing the bolts (A).

|

| Installation |

| 1. |

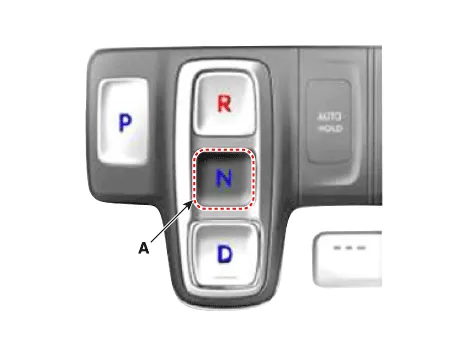

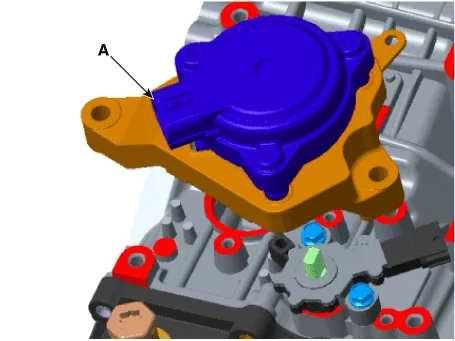

Check that the shaft (A) is in the "N" position.

|

| 2. |

Install the position sensor (B).

|

| 3. |

Install the position sensor "N" fixing SST(No.:09459 - 4G100)(D) in

the sensor (A), case pin (B) and anti-rotation guide (C).

|

| 4. |

Install the bolts (A) in the position sensor.

|

| 5. |

Remove the position sensor "N" fixing SST(No.:09459 - 4G100)(B).

|

| 6. |

Install the electric shift actuator (A).

|

| 7. |

Install the bolts (A).

|

| 8. |

Connect the electric shift actuator (A) and position sensor (B).

|

| 9. |

Install the air duct and the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

|

| 10. |

Install the battery and battery tray.

(Refer to Engine Electrical System - "Battery")

|

| 11. |

Check that operating surely at each range of the position sensor corresponding

to each position of electric shift button.

|

Specifications Specification ▷Type : Hall effect sensor Item Specification Operating condition (°C)°F (-40 to 150) -40 to 302 Output voltage (V) High 1.

Repair procedures Removal 1. Turn ignition switch OFF and disconnect the negative (-) battery cable. 2.

Other information:

Hyundai Palisade (LX2) 2020-2026 Service Manual: Evaporator Core

Repair procedures Replacement 1. Disconnect the negative (-) battery terminal. 2. Remove the heater and blower assembly. (Refer to Heater - "Heater Unit") 3.

Hyundai Palisade (LX2) 2020-2026 Service Manual: Front Radar Unit

Specifications Specification Item Specification Power supply (V) 12 Operation voltage (V) 9 - 16 Description and operation Description The smart cruise control unit is installed on the front right-hand side of the chass

Categories

- Manuals Home

- Hyundai Palisade Owners Manual

- Hyundai Palisade Service Manual

- Electronic Child Safety Lock System

- Body Electrical System

- Emergency liftgate safety release

- New on site

- Most important about car