Hyundai Palisade (LX2): Brake System / Repair procedures

| Operation and Leakage Check |

|

Check all of the following items :

|

Component |

Procedure |

||||

|

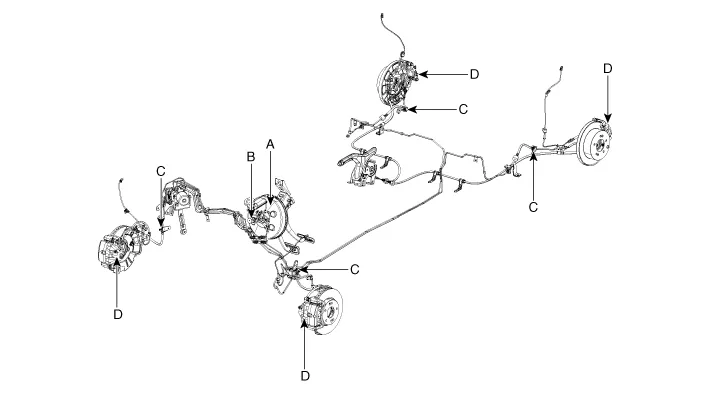

Brake Booster (A) |

Check brake operation by applying the brakes during a test drive. If the

brakes do not work properly, check the brake booster. Replace the brake

booster as an assembly if it does not work properly or if there are signs

of leakage. |

||||

|

Piston cup and pressure cup inspection (B) |

|

||||

|

Brake hoses (C) |

Look for damage or signs of fluid leakage. Replace the brake hose with a

new one if it is damaged or leaking. |

||||

|

Caliper piston seal and piston boots |

Check brake operation by applying the brakes. Look for damage or signs of fluid leakage. If the pedal does not work properly, the brakes drag, or there is damage or signs of fluid leakage, disassemble and inspect the brake caliper. Replace the boots and seals with new ones whenever the brake caliper is disassembled. |

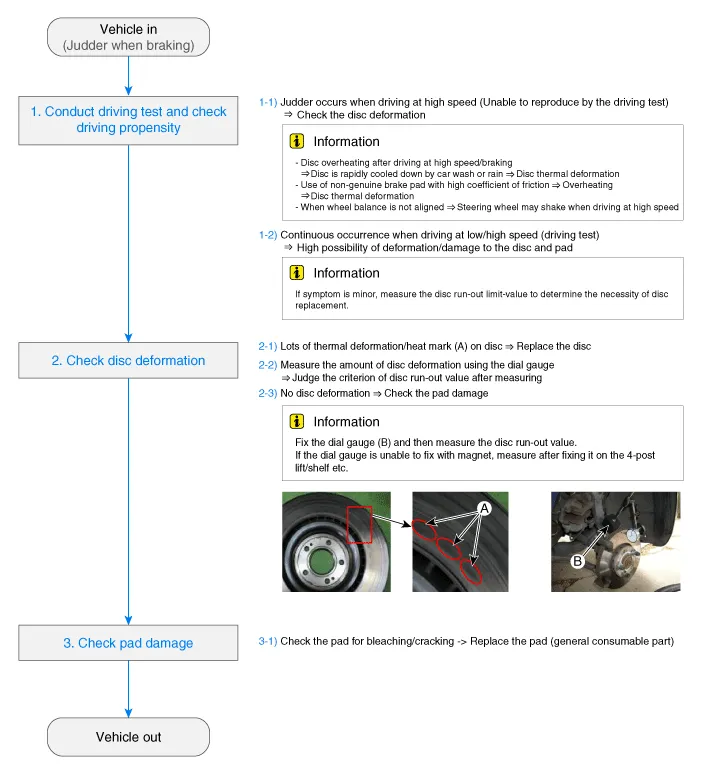

Brake System (Judder Inspection)

Components and components location Components 1. Reservoir cap 2. Reservoir 3. Brake booster 4. Master cylinder 5.

Other information:

Hyundai Palisade (LX2) 2020-2026 Service Manual: A/C Pressure Transducer

Description and operation Description The A/C Pressure Transducer (APT) converts the pressure value of high pressure line into voltage value after measuring it. By converted voltage value, engine ECU controls the cooling fan by operating it high speed or low speed.

Hyundai Palisade (LX2) 2020-2026 Service Manual: Warning Indicator

Components and components location Components 1. Warning indicator 2. SVM camera Repair procedures Removal 1. Disconnect the negative (-) battery terminal. 2.

Categories

- Manuals Home

- Hyundai Palisade Owners Manual

- Hyundai Palisade Service Manual

- Lift and Support Points

- Scheduled maintenance services

- Rear Bumper Cover

- New on site

- Most important about car

Copyright © 2026 www.hpalisadelx.com - 0.0489