Hyundai Palisade (LX2): Automatic Transaxle Control System / Position Sensor

Specifications

| Specification |

|

Item |

Specification |

|

|

Power supply (V) |

4.5 - 5.5V |

|

|

Output type |

Shifting range |

Non-contact (2 channel PWM signal) |

Description and operation

| Description |

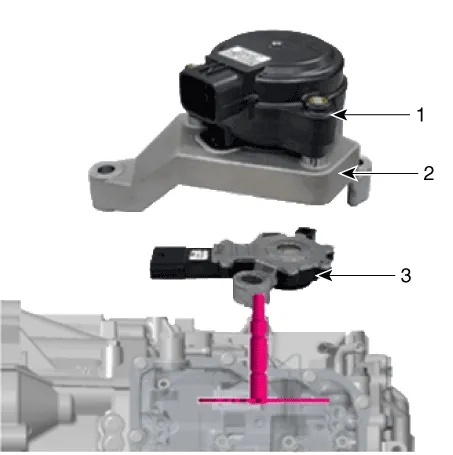

| 1. Electric shift actuator

2. Bracket 3. Position sensors |

Troubleshooting

| Troubleshooting |

|

Major Symptom |

Expected Cause |

Items to Check and Measures |

|

Shock when shifting to and from D/R Motor run-up when shifting to and from D/R |

Faulty position sensor "N" setting |

Use the "N" setting jig and adjust the "N" setting. (Refer to "Automatic Transaxle System – Position Sensor") |

|

Faulty oil pressure in the valve body |

Replace valve body assembly or inspect/replace transaxle assembly |

|

|

Faulty engine start Current gear not indicated in the Cluster Warning Lamp ON Engine stall while stopped Creeping not possible Auto parking release disabled |

Faulty CAN terminating resistance/circuit |

Check TCM/battery management system module. |

|

Check TCM wiring connector connection. |

||

|

Faulty position sensor circuit fuse |

Check fuse and junction box terminal, and repair. |

|

|

Faulty position sensor wiring connector |

Check for foreign substance in the wiring connector, and check for gap on

the terminal. |

|

|

Check sealing on unused pin, and check for corrosion on the terminal. |

||

|

Faulty reverse lamp circuit |

Check reverse lamp ground, and reassemble if necessary. |

|

|

Faulty position sensor wiring ground |

Check wiring ground, and reassemble if necessary. |

|

|

Position sensor faulty code |

Inspect in accordance with the inspection flow, then replace position sensor

if necessary. |

Repair procedures

| Removal |

|

| 1. |

Turn ignition switch OFF and disconnect the negative (-) battery cable.

|

| 2. |

Remove the battery and battery tray.

(Refer to Engine Electrical System - "Battery")

|

| 3. |

Remove the air duct and the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

|

| 4. |

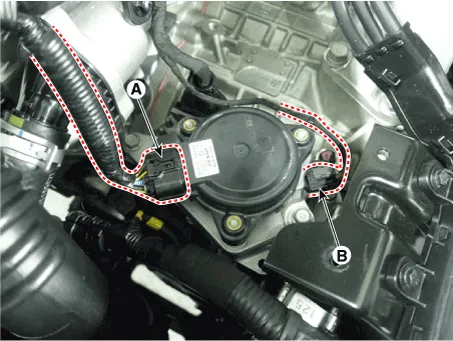

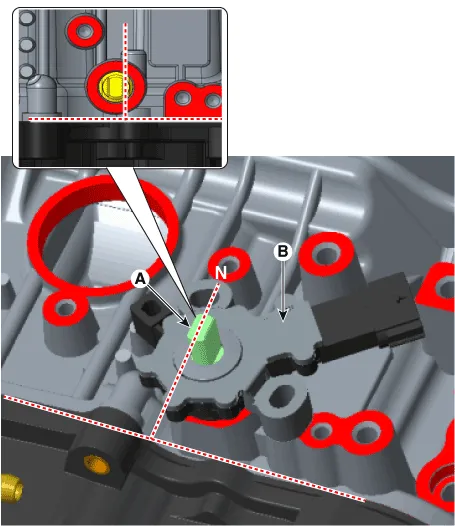

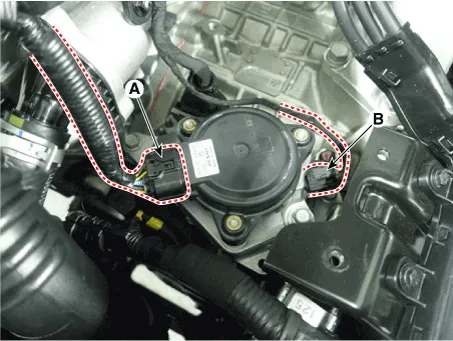

Disconnect the position sensor connector (A).

|

| 5. |

Disconnect the electronic shift actuator connector (B).

|

| 6. |

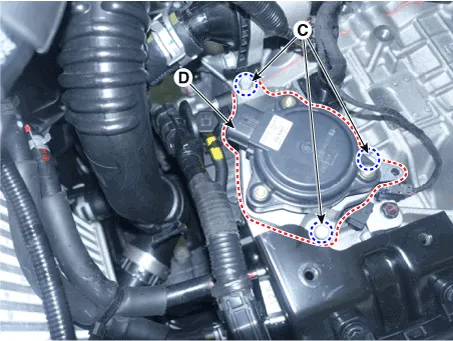

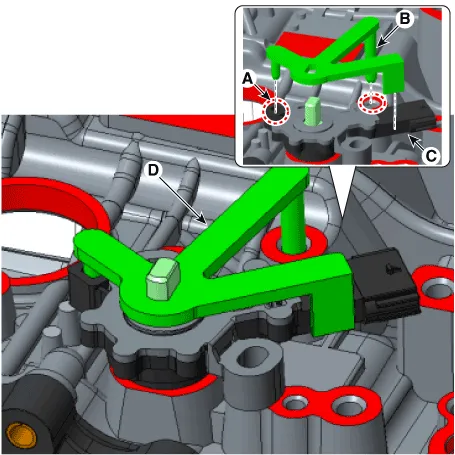

Remove the electronic shift actuator (D) after removing the bolts (C).

|

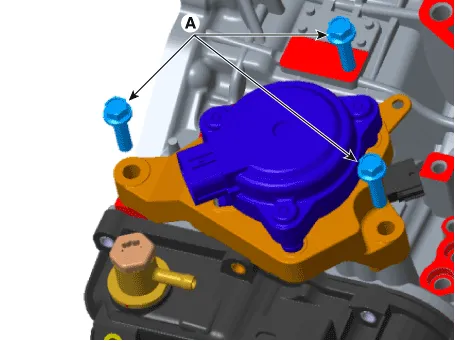

| 7. |

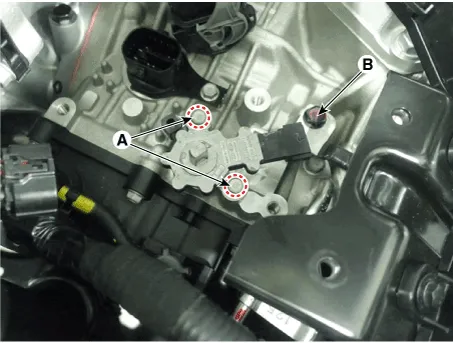

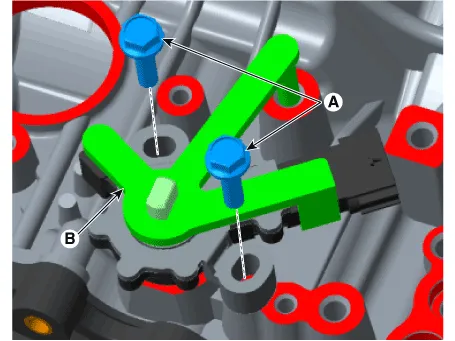

Remove the position sensor (B) after removing the bolts (A).

|

| Installation |

| 1. |

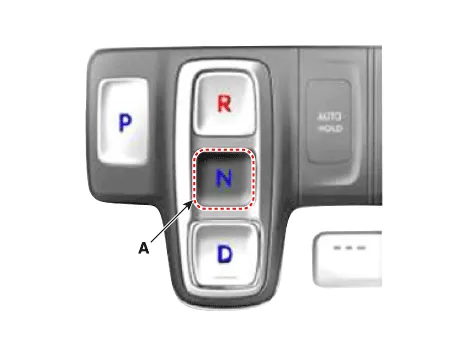

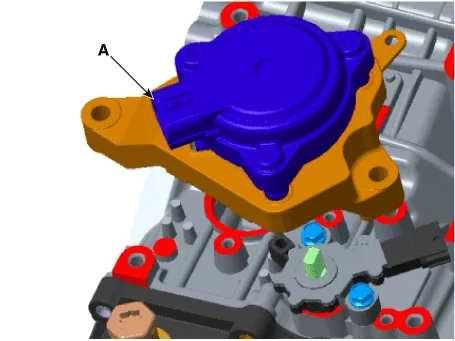

Check that the shaft (A) is in the "N" position.

|

| 2. |

Install the position sensor (B).

|

| 3. |

Install the position sensor "N" fixing SST(No.:09459 - 4G100)(D) in

the sensor (A), case pin (B) and anti-rotation guide (C).

|

| 4. |

Install the bolts (A) in the position sensor.

|

| 5. |

Remove the position sensor "N" fixing SST(No.:09459 - 4G100)(B).

|

| 6. |

Install the electric shift actuator (A).

|

| 7. |

Install the bolts (A).

|

| 8. |

Connect the electric shift actuator (A) and position sensor (B).

|

| 9. |

Install the air duct and the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

|

| 10. |

Install the battery and battery tray.

(Refer to Engine Electrical System - "Battery")

|

| 11. |

Check that operating surely at each range of the position sensor corresponding

to each position of electric shift button.

|

Specifications Specification ▷Type : Hall effect sensor Item Specification Operating condition (°C)°F (-40 to 150) -40 to 302 Output voltage (V) High 1.

Repair procedures Removal 1. Turn ignition switch OFF and disconnect the negative (-) battery cable. 2.

Other information:

Hyundai Palisade (LX2) 2020-2026 Service Manual: Blower Unit

Components and components location Components Location 1. Blower unit assembly Components 1. Intake seal 2. Intake upper case 3. Intake actuator 4. Intake door 5.

Hyundai Palisade (LX2) 2020-2026 Service Manual: Schematic diagrams

System Block Diagram Component Parts And Function Outline Component part Function Vehicle-speed sensor, ESP/ABS Control Module Converts vehicle speed to pulse. ECM Receives signals from sensor and control switches.

Categories

- Manuals Home

- Hyundai Palisade Owners Manual

- Hyundai Palisade Service Manual

- Convenient Features of Your Vehicle

- Maintenance

- Electronic Child Safety Lock System

- New on site

- Most important about car