Trouble Symptom

|

Probable Cause

|

Remedy

|

Coolant leakage

|

| • |

From the bleed hole of the water pump

|

|

Visually check

|

| • |

Check leaks after about 10 minutes of warming up.

|

|

| • |

If coolant still leaks, replace the water pump.

|

|

| • |

If leakage stops, reuse the water pump. (Do not replace the

pump with a new one.)

|

|

| • |

From gaskets or bolts

|

|

| • |

Check the tightening of the water pump mounting bolts.

|

|

| • |

Retighten the mounting bolts.

|

|

| • |

Check damage of gaskets or inflow of dust.

|

|

| • |

Replace the gasket and clean dust off.

|

|

| • |

From outer surface of water pump

|

|

| • |

Check the material for any cracks of the water pump.

|

|

| • |

Material defect. If any cracks are found, replace the water

pump.

|

|

Noise

|

| • |

From mechanical seals

|

| • |

Impeller interference

|

|

Inspection with a stethoscope

|

| • |

After starting the engine, check noise with a stethoscope.

|

|

| • |

If there is no noise, reuse the water pump (do not replace it).

|

|

| • |

If there is any noise from the water pump, remove the drive

belt and recheck.

|

|

Inspection after removing the drive belt.

|

| • |

After removing the water pump and the drive belt, check noise

again.

|

|

| • |

If there is noise, reuse the water pump. Check other drive line

parts.

|

|

| • |

If there is no noise, replace the water pump with a new one.

|

|

Inspection after removing the water pump

|

| • |

After removing the water pump and the drive belt, check noise

again.

|

|

| • |

If there is any interference between them, replace the water

pump with a new one.

|

|

Overheating

|

|

Loose impeller

|

| • |

Corroded impeller wing

|

|

| • |

Check engine coolant.

|

| • |

Poor coolant quality / Maintenance check

|

|

| • |

Impeller seperated from the shaft

|

|

| • |

Replace the water pump.

|

|

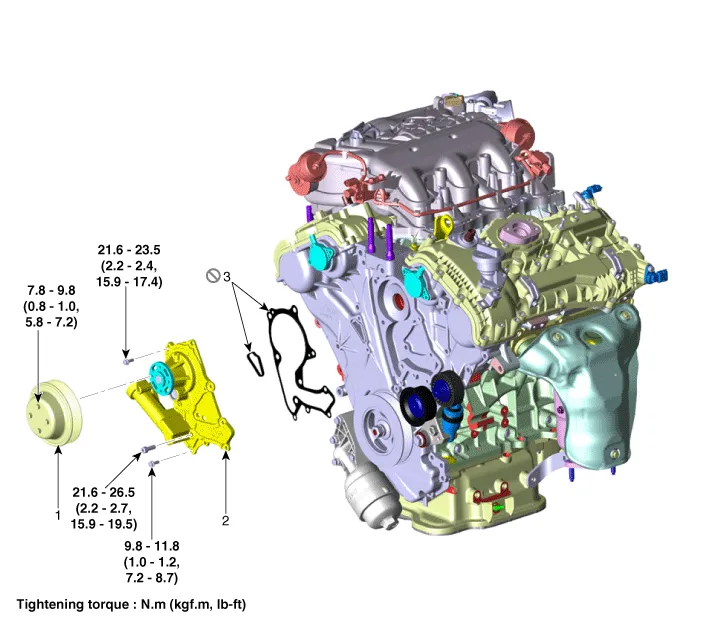

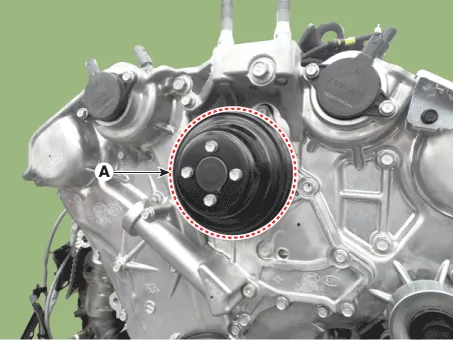

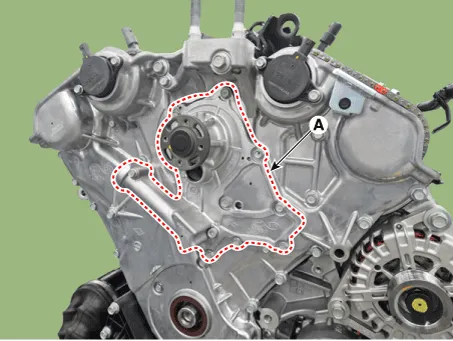

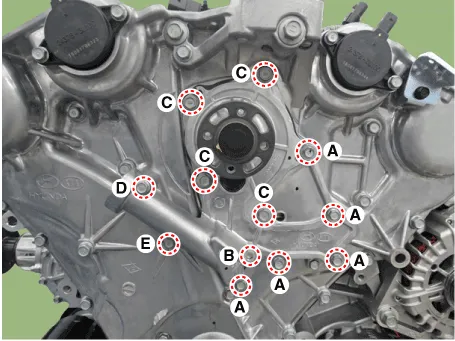

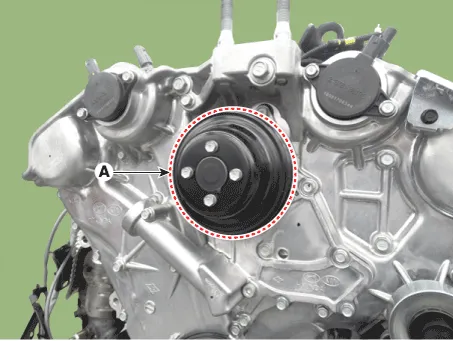

Repair procedures

Removal and Installation

•

Be careful not to damage the parts located under the vehicle

(floor under cover, fuel filter, fuel tank and canister) when

raising the vehicle using the lift.

Description and operation

Description and Operation

Electric Thermostat (ECT)

Overview

Optimal control of coolant temperature depending on the driving conditions

Operation Principle

Electric Thermostat (ECT) Structure

Repair procedures

Removal

•

Be careful not to damage the parts located under the vehicle

(floor under cover, fuel filter, fuel tank and canister) when

raising the vehicle using the lift.

Other information:

Description and operation

Description

The In-car air temperature sensor is built in the heater & A/C control unit.

The sensor consists of a thermistor that measures the inside temperature. The

signal decided by the resistance value that changes in accordance with perceived

inside temperature, is delivered to heater co

Description

Blind-Spot Radar is a system that measures the relative speed and distance from

the following vehicles by using two electromagnetic wave radar sensors attached

to the rear bumper, and detects any vehicle within the blind spot zone and gives

off alarm (visual and auditory).